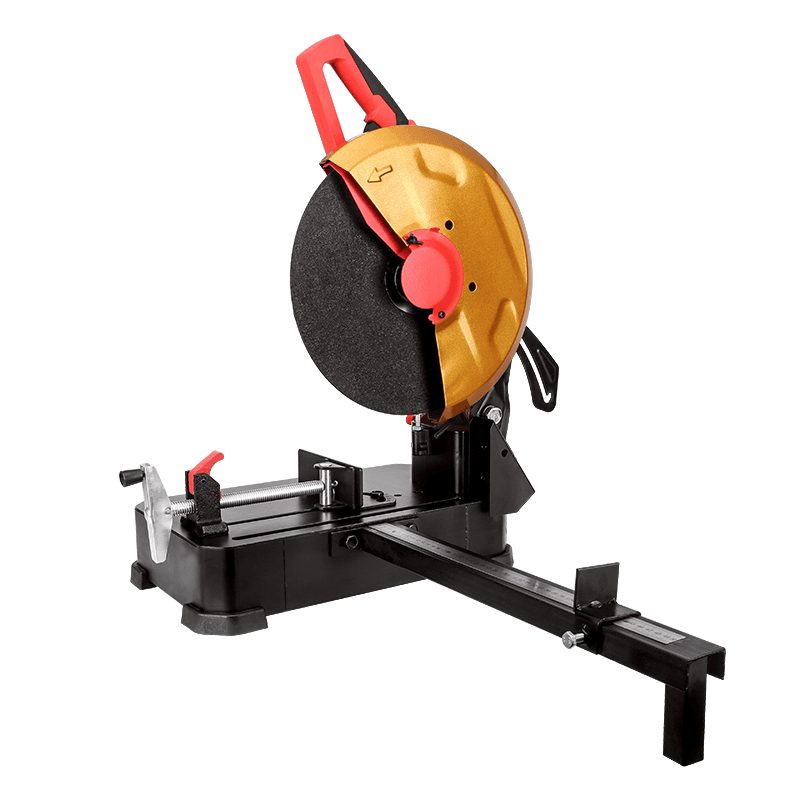

ZB-355G-1 Industrial Steel Cutting Machine

The ZB-355G-1 Industrial Steel Cutting Machine is engineered for high-performance metal cutting tasks. Equipped with a robust 3000W motor and a 355mm (14-inch) blade, it delivers precise and efficient cuts through various metals, including steel and aluminum. Its durable construction and advanced features make it an ideal choice for industrial applications, ensuring reliability and longevity in demanding work environments.

- Powerful Motor: 3000W motor provides substantial power for heavy-duty cutting operations.

- Large Blade Diameter: 355mm blade accommodates a wide range of metal cutting applications.

- High No-Load Speed: Operates at 3800 RPM for swift and efficient cutting performance.

- Adjustable Cutting Angle: Facilitates precise angled cuts to meet diverse project requirements.

- Safety Features: Includes a spark guard and ergonomic handle for user protection and comfort.

- Durable Construction: Built with high-quality materials to withstand rigorous industrial use.

- Model Number: ZB-355G-1

- Rated Voltage: 220V-50Hz

- Rated Input Power: 3000W

- No-Load Speed: 3800 RPM

- Blade Diameter: 355mm (14 inches)

- Cutting Capacity: Up to 100mm

- Motor Height: 60mm

- Net Weight: 25kg

- Gross Weight: 26kg

- Packaging Dimensions: 63 x 34 x 44 cm

- Selling Units: Single item

- Package Size: 63 x 34 x 44 cm

- Gross Weight: 26 kg

- Packaging Details: Each unit is securely packaged with full foam protection, placed in a color box, and enclosed within a master carton to ensure safe transit.

- Supply Ability: Up to 8,000 pieces per week

- Lead Time:

- 1-1000 pieces: Approximately 15 days

- More than 1000 pieces: To be negotiated

The ZB-355G-1 Industrial Steel Cutting Machine comes with a 1-year warranty covering manufacturing defects. Customers can access OEM, ODM, and OBM support services to tailor the product to specific business needs. For assistance, contact our customer support team or visit our website for more information.

Why are Steel Cutting Machines used?

Steel cutting machines, such as the ZHIBIAO ZB-355G-1 Industrial Steel Cutting Machine, are vital tools for achieving precise, efficient, and reliable cuts in various industries. Their advanced technology and powerful features make them ideal for a wide range of applications, including:

Metal Cutting: The ZB-355G-1 is specifically designed for cutting steel, aluminum, and iron with high precision. It is widely used in construction, manufacturing, and automotive industries for producing accurate and consistent results.

Versatility in Material Cutting: While optimized for steel, the ZB-355G-1 can also handle other materials like PVC and aluminum, making it a flexible tool for various projects and applications.

Durability and Strength: Built to withstand rigorous use, this machine ensures long-lasting performance and is suitable for demanding industrial environments.

Precision and Accuracy: Equipped with a 14-inch blade and high-powered motor, the ZB-355G-1 ensures straight, clean cuts that meet exact specifications. This precision is essential for engineering, fabrication, and other detailed projects.

Efficiency and Speed: The ZB-355G-1’s powerful motor operates at 3800 RPM, enabling fast, repetitive cuts and significantly improving productivity in workshops and factories.

Safety and Performance: Features such as a spark guard and ergonomic design provide a safer user experience, reducing the risks associated with metal cutting operations.

With its powerful motor, precision engineering, and user-friendly design, the ZHIBIAO ZB-355G-1 Steel Cutting Machine is a reliable choice for professionals seeking accuracy, efficiency, and high performance in their cutting tasks.

Package and Delivery

Our factory is equipped with modern, advanced machinery, ensuring efficient production processes and high-quality output. With precise manufacturing capabilities, we deliver top-notch cut-off machines that meet global standards.

Experience Precision and Efficiency with Our Cold Cutting Machine

At Precision Cold Cutting Solutions, we specialize in delivering top-tier cold cutting machines engineered for exceptional accuracy and efficiency across diverse applications. Our state-of-the-art equipment is designed to handle various materials, including metals and composites, ensuring clean cuts without heat distortion. Built to endure demanding usage, our machines consistently provide precise results, enabling you to complete projects with utmost accuracy and speed. Explore our extensive selection of cold cutting machines tailored to meet your specific material and cutting requirements.

Related Product

Our extensive range of cut-off machines caters to various industries and applications. From industrial workshops to construction sites, we have the perfect machine for your cutting requirements.

Frequently Asked Questions

Most frequent questions and answers

A: Yes, sample order is available for quality check and market test.

A: It usually takes about 15-25 days for production depending on your order quantity.

A: Different model has different MOQ, so please contact with us before you send order.

A: Yes, we can. Welcome to do OEM. Please email us to talk about the details.

A: We usually accept 30% deposit,balance against BL copy.

A: When operating a cut-off machine, it is important to wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and ear protection. Ensure that the work area is clear of obstructions and that the machine is securely positioned. Follow all safety guidelines outlined in the user manual to prevent accidents.

A: Regular maintenance is crucial to ensure the longevity and optimal performance of your cut-off machine. Refer to the user manual for specific maintenance intervals and tasks such as cleaning, lubrication, and inspection of key components. Additionally, consider having your machine professionally serviced at recommended intervals or if you notice any signs of malfunction.

A: Yes, we provide customization services to meet your specific design and material requirements. Reach out to us for further details.