Introduction: Cut Off a Machine have been handed a difficult challenge. Introducing new products or services to your audience without a marketing or advertising budget can be challenging. Social media outreach may not yield the expected results. What do you do?

Table of Contents

ToggleHow to Cut Off a Machine.

Machines are tools that people use to perform various tasks. They come in different shapes and sizes, and the most popular ones are those used for chopping, slicing, and drilling.

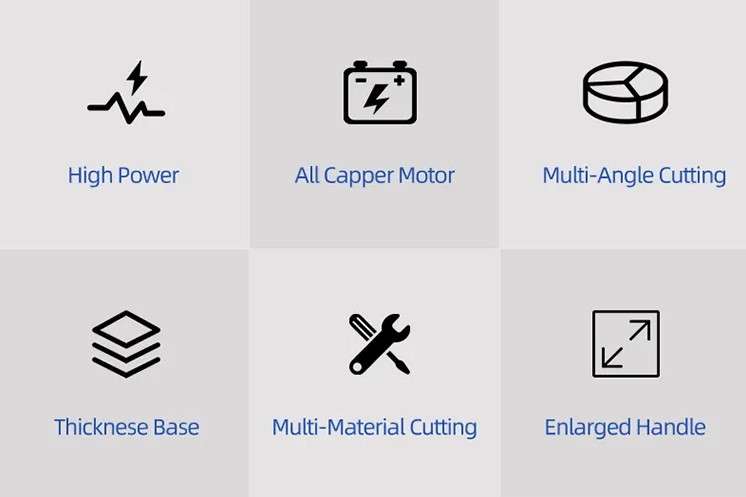

To cut off a machine, you will need to know what it is and how to use it. To understand how to cut off a machine, you first need to know what a machine is in general terms. A machine is made up of many parts:

-The body: This is the part that the machine sits on (the frame).

-The tools: These are the pieces of equipment that you use to operate the machine.

-The motor: This provides power for the tools and helps them move around (it’s typically attached near the front or back of the machine).

-The blades: These are special pieces of machinery that help with cutting tasks by slicing through materials quickly and accurately.

How to Cut Off a Machine.

People use machines as tools to accomplish different tasks. For instance, a computer is a machine that helps with decision-making and printing documents.

There are several ways to cut off machines, but the most common way is to use a sword or knife. Sword users can cut through the metal with ease while knife users may need to be careful not to cut into the delicate circuitry of a machine. To remove a machine using either form of destruction, be sure first that the machine is safe to handle before trying to slice it open.

Tips for Cut Off Machines.

One of the most important things you can do in order to keep your machine safe is to take it easy on the cutting edge. Keep your blade clean, honed, and free from nicks and cuts. When operating cutting machines, ensure your safety by wearing appropriate gear like a helmet, long sleeves, and pants to avoid injuries.

Use aissors to Cut the Machine.

If you’re having trouble cutting through a stubborn piece of metal, try using a pair of scissors instead. A pair of scissors can be used in place of a knife to cut through materials such as fabric or plastic. Just make sure that your hands are clear of the blade at all times so that you don’t hurt yourself.

Use aplication Shears to Cut the Machine.

If you want to chop something very small or if there is too much material for either knife or scissors to reach, you may need to use an application shears. People use application shears for cutting objects smaller than 1 inch (2 cm). These are special-purpose blades designed for this purpose. Simply place the object onto one end of the shears and then cut away at its surface with the other end of the shears. People often use this technique to navigate tight spaces or trim down large machinery pieces.

Use a Knife to Cut the Machine.

To cut tough materials like metal or wood, it’s better to use a specialized tool like an axe or hammer instead of a knife. Make sure to only strike the target material and avoid hitting anything else to prevent damage and achieve clean cuts.

Conclusion

In order to cut off a machine, there are a few things you need to know. Firstly, it’s important to understand the purpose of the machine- whether it’s for personal use or frequent operation. This helps ensure that you comprehend its functions. Next, make sure you have the proper tools- including an application blade and a knife. Finally, be careful- not only should you cut slowly and carefully, but you also want to avoid cutting yourself. If any of these tips don’t work for you or if something dangerous happens while trying to cut off a machine, always seek professional help!